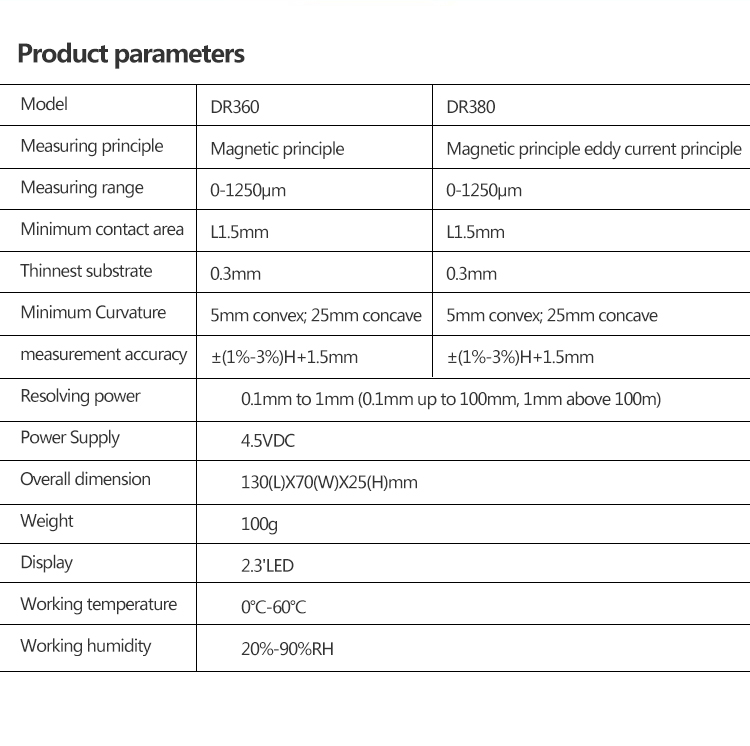

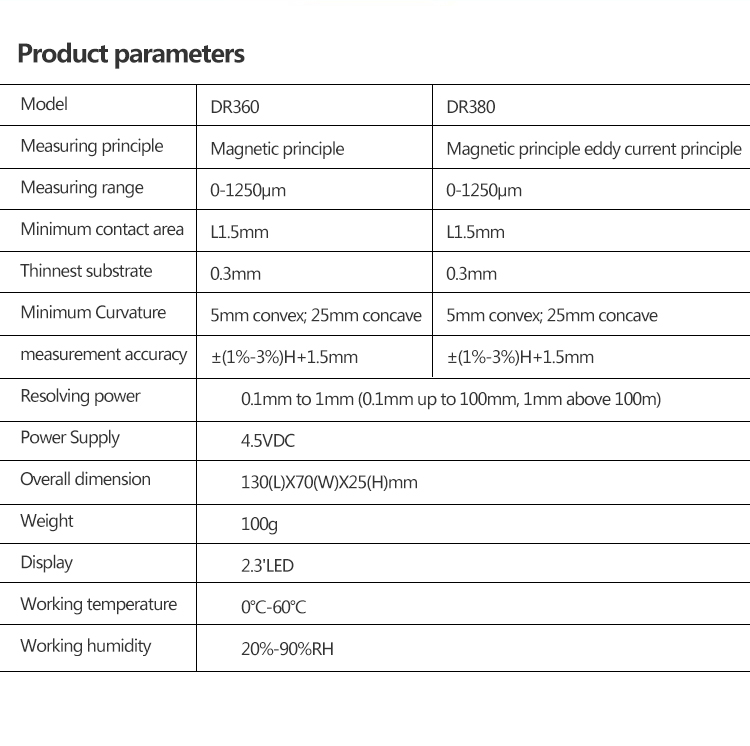

Coating Thickness Gauge

Introduction of DR360 Coating Thickness Gauge

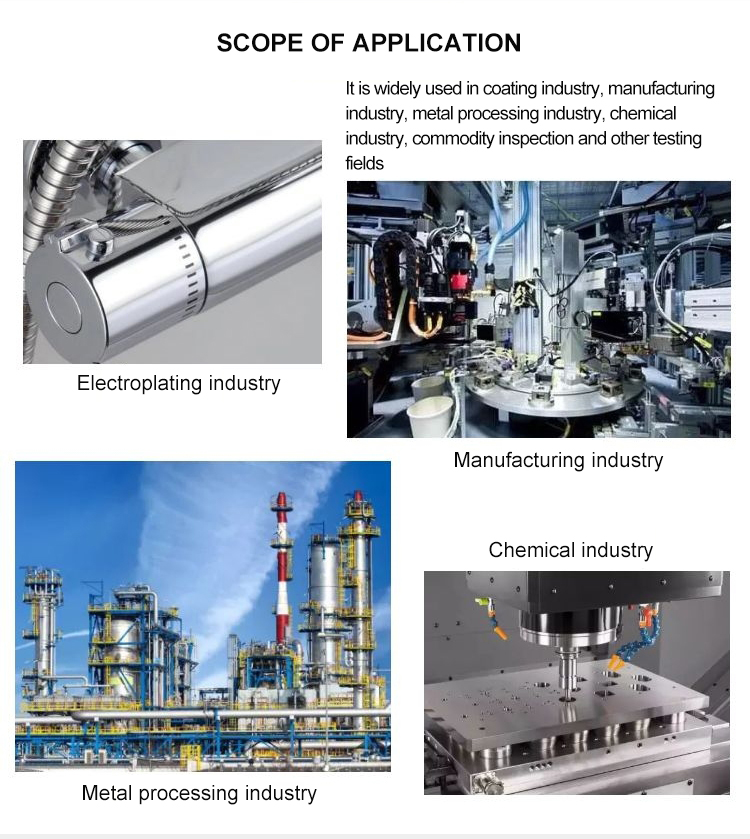

The DR360 coating thickness gauge is a professional non-destructive testing instrument for measuring the thickness of objects covered with coating on the surface of magnetic metal materials. It adopts the magnetic thickness principle, and can quickly and non-destructively measure the thickness of non-magnetic coatings (galvanization, chrome, confinement, enamel, rubber, powder, paint, electrophoresis, enamel, plastic spraying, coating, anti-corrosion and fireproof coating, etc.) on magnetic metal substrates (e.g., steel, iron). The instrument has a precise and solid structure, good repeatability, good performance, easy to use and convenient to carry. It is widely used in the coating industry, manufacturing industry, metal processing industry, chemical industry, commodity inspection and other testing fields.

Instrument Features

- Simple operation, fast testing speed, good sensitivity, high measurement accuracy

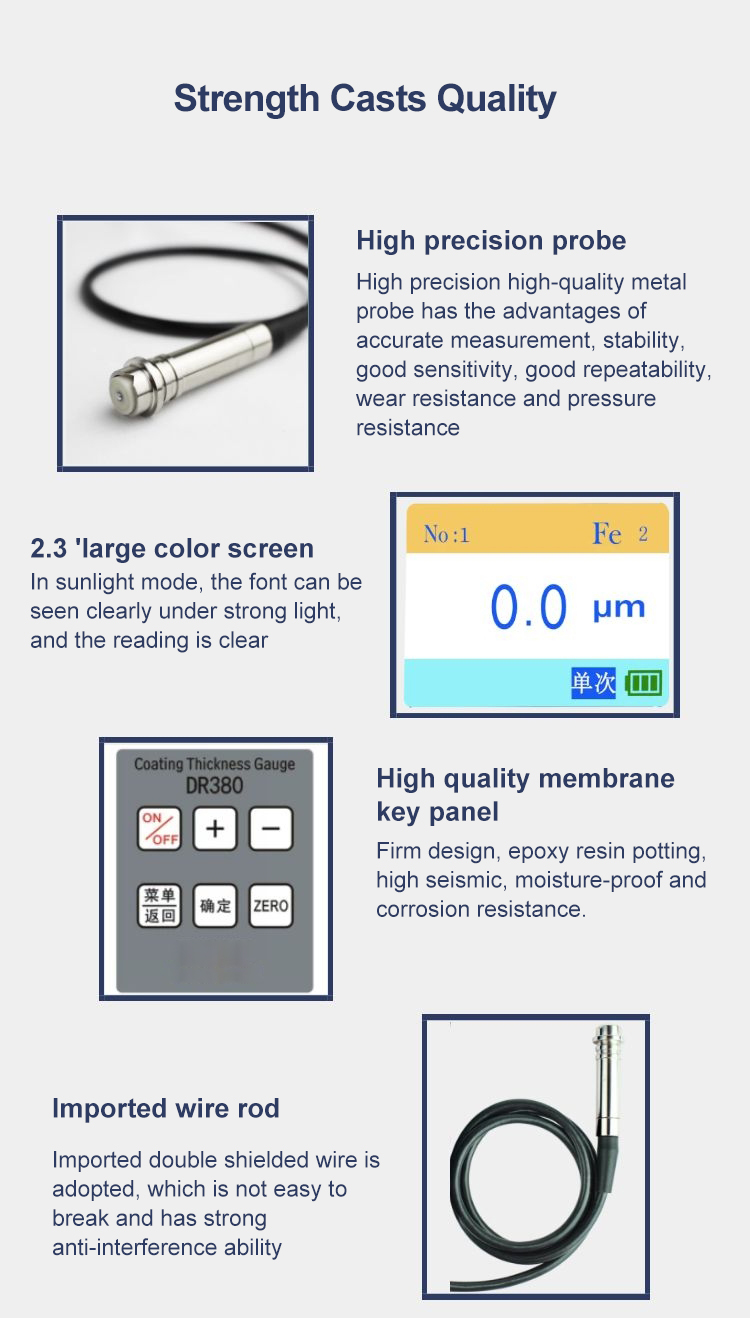

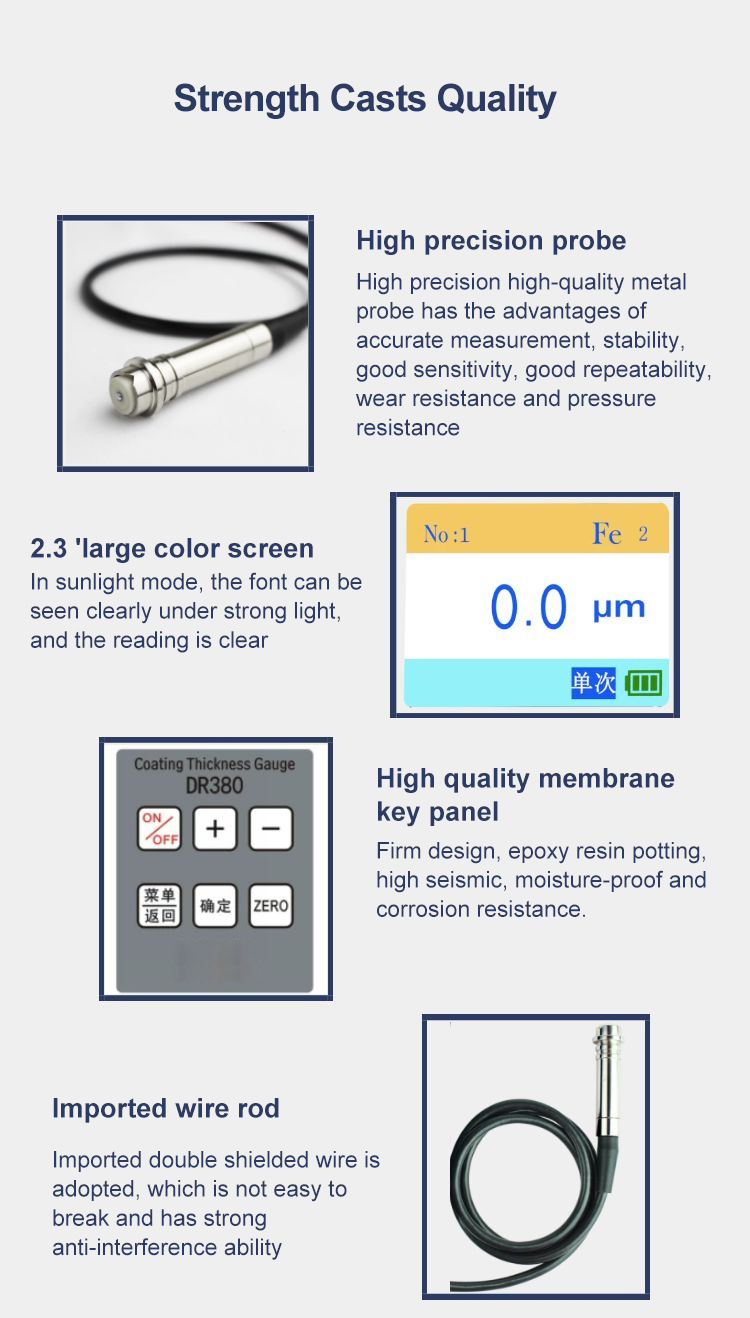

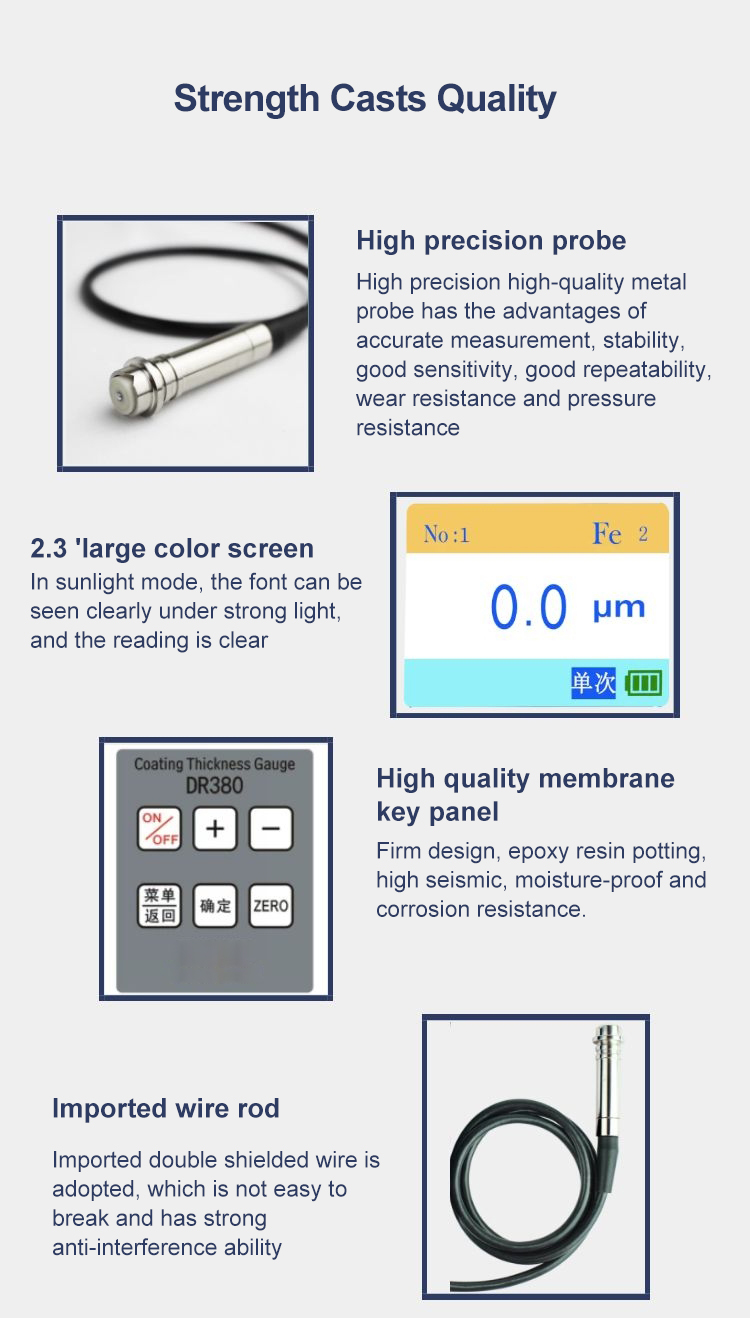

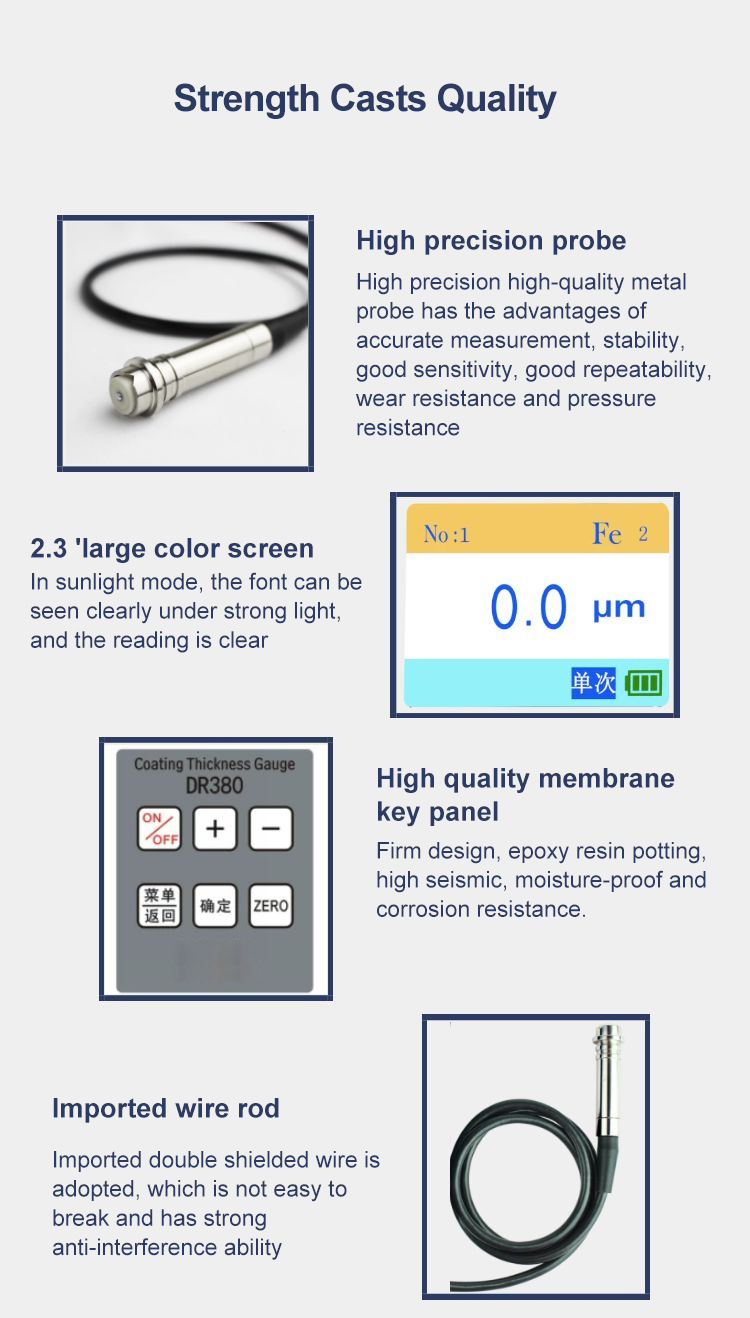

-Using alloy probes, being wear-resisting, pressure-resisting, durable and accurate

-Two measurement methods: continuous and single measurement

- Four statistical functions: maximum value (MAX), minimum value (MIN), average value (MEA), number of measurements (No)

- Large storage capacity in 10 groups of 200 data each, for a total of 2000 data

- Data storage and deletion function

- Three types of calibration: zero calibration, two-point calibration, multi-point calibration

- Upper and lower limit alarm function (can be set in single measurement mode)

- Beeping sound to indicate operation (in single measurement mode)

- Automatic recognition of iron-based and non-iron-based substrates

- Metric to imperial conversion μm/Mil

- Sunlight mode (for use in bright light)

- Dual language versions in English and Chinese

- Large 2.3" color screen with large font size display

- Manual/automatic switch-off function